Every year, Uganda produces 3 million tons of waste. Of this, only 8% is recycled with the rest ending up in the environment. Plastics, especially from the water and beverage industry make up the biggest percentage of the country’s non-biodegradable waste.

These plastics lie in landfills for years without decomposing thereby releasing toxic substances as they are subjected to the effect of sunlight. They also contaminate the air when burned releasing toxins through ambient air pollution.

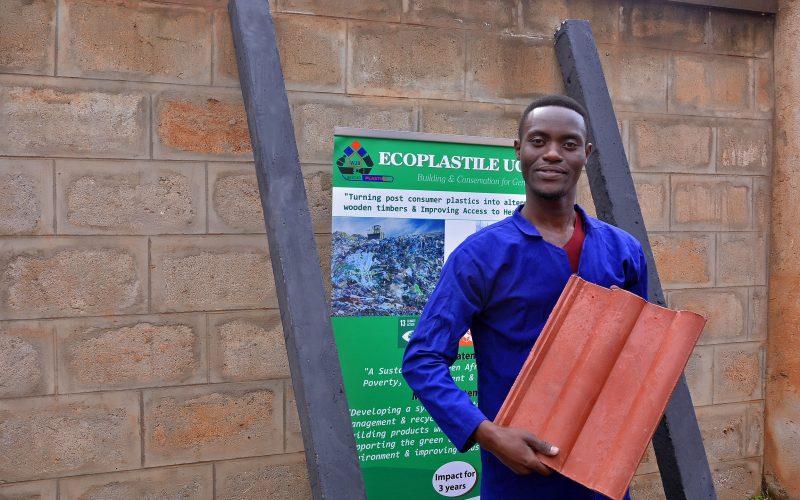

EcoPlastile a local start-up uses energy-conserving technology called ‘Waxy 2 technology’ and chemical-free processes to recycle plastic garbage into reusable plastic building timbers. The company which focuses on waste management and construction is working to address Uganda’s challenges of urban waste management.

As a sustainable alternative to wood, plastic timbers reduce the need for wood-based building materials. This preserves forests as the level of deforestation is significantly reduced. Finding alternatives to wood has the potential to mitigate the effects of climate change, which if left unabated poses serious problems to human life as we currently know it.

Located in Namanve Industrial Area, EcoPlastile has built a model that allows slum residents to collect plastic waste in exchange for medical care. The firm currently recycles 10 different types of plastics into termite resistance plastics that are applied in building and construction.

Franc Kamugyisha the founder of the company was inspired by this own experience living in a slum in Kampala. On his arrival to the city from the village as he sought work, he could only afford cheap accommodation in a slum until the winds of favor blew his way. It was while living in these conditions that he saw first-hand the consequences of poor waste disposal.

“In the slum, there is no waste pickup trucks because people simply cannot afford to pay for waste pickup services. Left with no option, late in the night we would dump our waste in drainage channels in the neighborhoods,” he says. The blocked drainage channels would lead to other problems such as flooding when it rained leading to the displacement of people from their homes.

To date, EcoPlastile has recycled more than 150 tons of plastic and created job opportunities for more than 150 young men and women directly and indirectly. The company has also expanded the range of products it makes from recycled plastics which now include roofing tiles, pavers, floor tiles and plastic lumbers which are used as wire fence support pillars.